DATA INSIGHT'S PROJECT

Data Insight's project is a successful effort that creates intelligent and effective data analysis solutions for businesses, helping them make smart decisions based on data and improve their business efficiency.

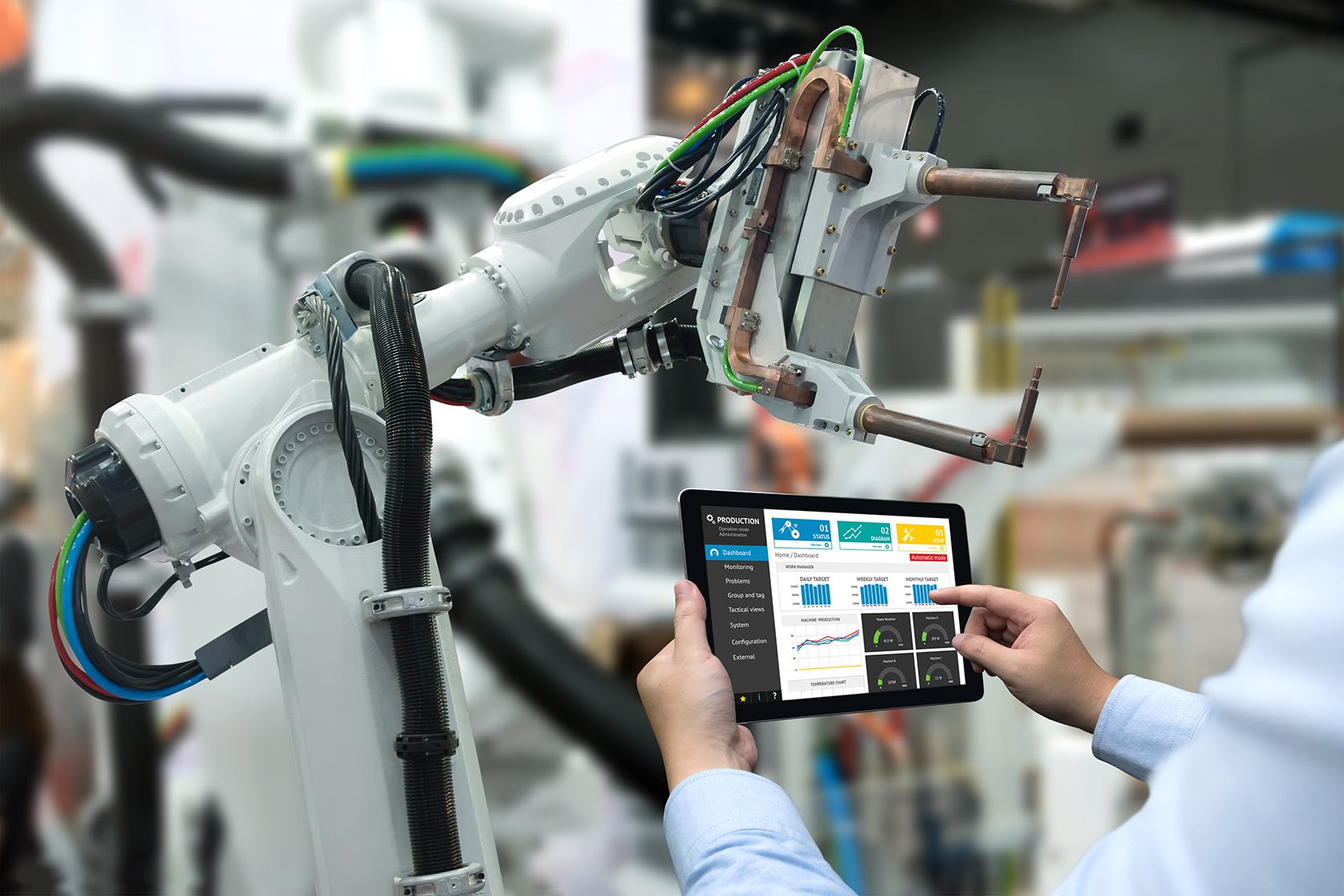

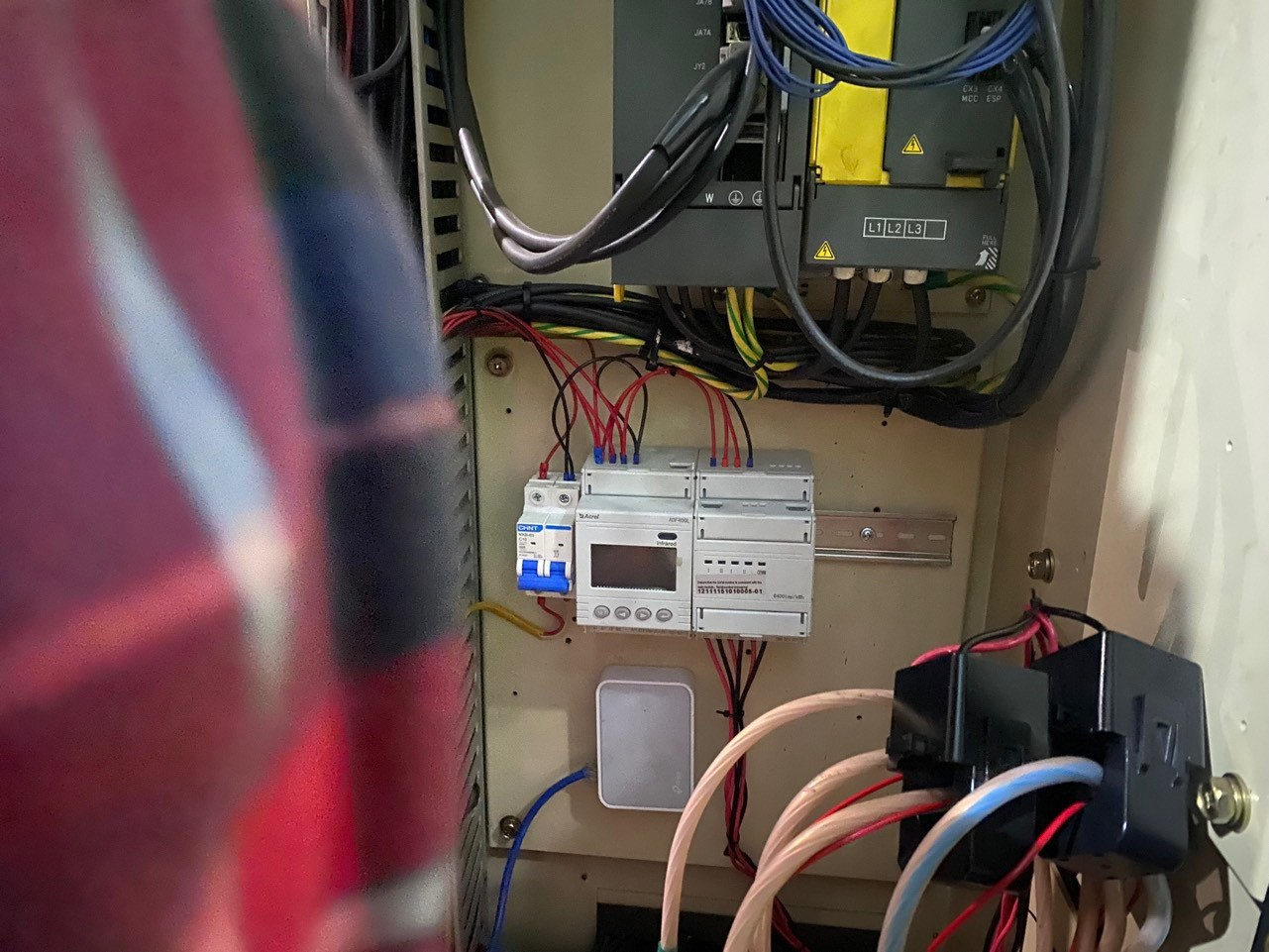

Data Collection Software for Driving Shop Floor Optimization

Automated data collection software optimizes production, boosts productivity, and reduces costs for your business. ...

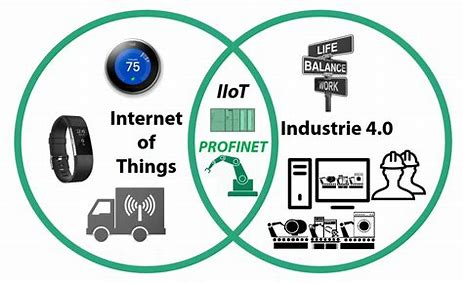

IIoT Platforms: To build your own or to partner with the pros?

Discover the optimal choice for your IIOT platform: build in-house with your team or collaborate with top industry experts. ...

Remote Machine Monitoring: A Game-changer for Manufacturers

Remote Machine Monitoring: A breakthrough solution that helps businesses optimize performance, minimize downtime, and enhance productivity! ...

Using Cloud Software for Increased Productivity

Increase production efficiency with cloud software: Optimize processes, reduce costs, and enhance efficiency for your business. ...

Finding the Right Cloud Solution for Manufacturers

Find the optimal cloud solution for manufacturers, enhancing efficiency, saving costs, and ensuring maximum security with cloud software. ...

Four key benefits of PaaS for Manufacturers

4 Key Benefits of PaaS for Businesses: Cost Savings, Accelerated Development, Seamless Scalability, and Enhanced Security—Today! ...

What is Equipment-as-a-Service? The benifits of EaaS

Equipment as a Service (EaaS) offers cost-saving solutions and performance optimization, enabling businesses to focus on their core values. ...

Concern about SaaS and Cloud? Here’s what you need to know

Discover the Power of Cloud and SaaS Platforms! Learn essential insights to optimize technology and boost your business performance. ...

How Cloud and SaaS make Smart Manufacturing Cheaper, Secure

Discover how Cloud and SaaS help reduce production costs and enhance security, bringing optimal efficiency to your business! ...

5 Advantages of SaaS for Manufacturers

5 Benefits of SaaS for Manufacturing Businesses: Cost Optimization, Flexible Scalability, Fast Updates, Easy Access, and High Security. ...

Difference between Takt Time vs Cycle Time vs Lead Time

Explore the differences between Takt Time, Cycle Time, and Lead Time in production to optimize efficiency and productivity for your business. ...

What is cycle time? How to calculate and reduce cycle time

Cycle time measurement: Optimizing production processes, reducing completion time, and enhancing work efficiency. ...

Four benefits of PaaS for Manufacturers

PaaS provides significant advantages for manufacturing enterprises by optimizing resources and increasing production efficiency. ...

Two trends in sustainable manufacturing

Explore sustainable manufacturing trends and their positive impact on the environment and society. Let's delve into the current advancements. ...

Why most Industrial IOT Implementations fail?

Optimize manufacturing with industrial IoT: enhance efficiency, improve safety, and automate processes with smart connectivity. ...

How to identify and solve production issues with data analysis

Data analysis: Identify and address production challenges, optimize processes, reduce costs, and increase operational efficiency. ...

What is Scrap? How to reduce scrap in manufacturing

Data Insight helps manufacturing businesses reduce scrap with advanced data analytics, optimizing and improving product quality. ...

A long-term strategy for manufacturers adopting industry 4.0

Industry 4.0 brings revolutionary technologies to optimize processes, improve product quality, and increase overall plant productivity. ...

What is Takt Time? How to calculate and reduce this key metric

Ensuring you have the accurate data necessary to track and reduce takt time is increasingly important given growing market competition. ...

Lean manufacturing: The Principles, Wastes, Benefits, and Tools

Lean manufacturing is an approach to continuous improvement and sustainability through the holistic elimination of waste and inefficiencies. ...

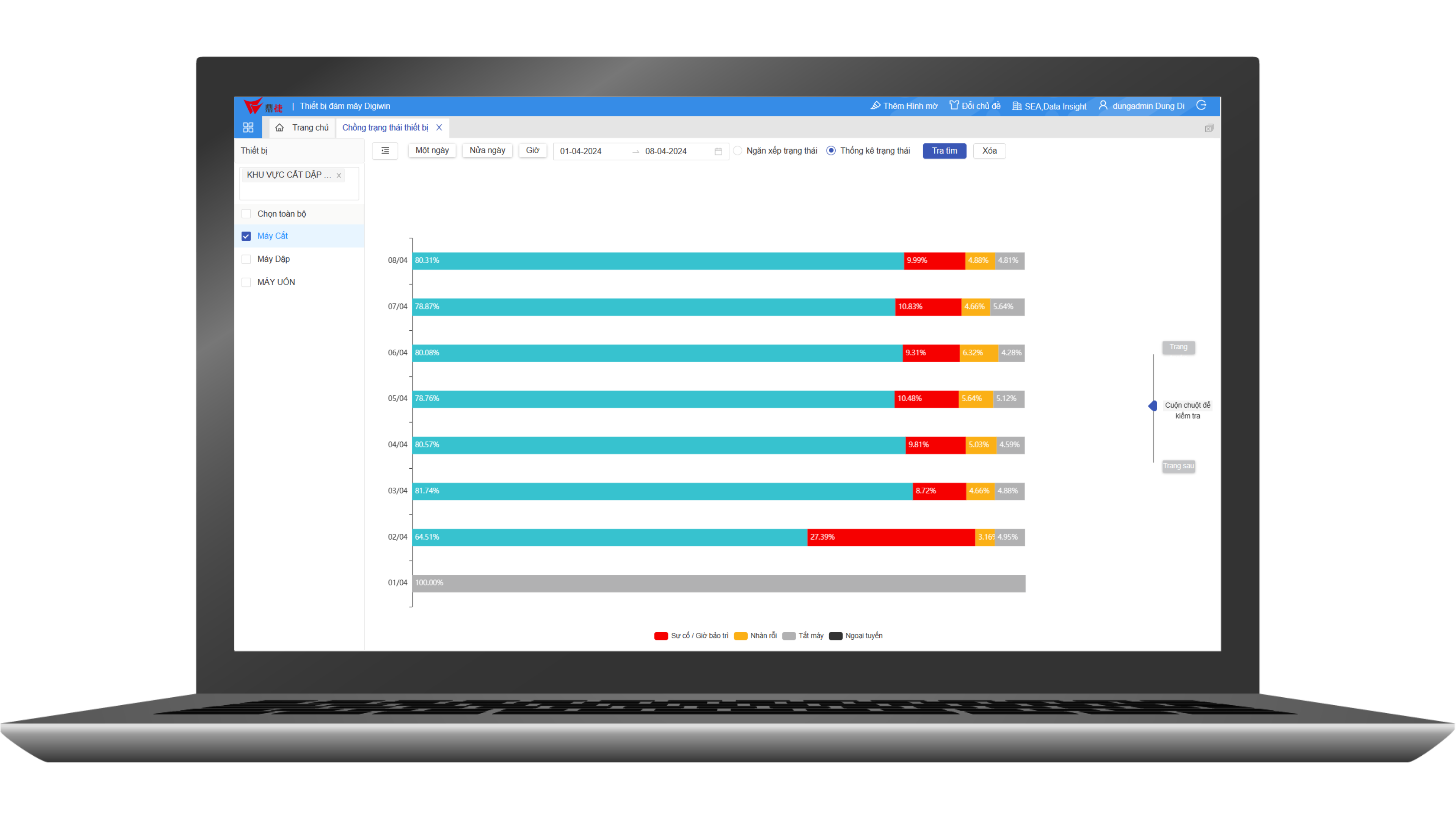

How to calculate and improve Machine Availability

Understand your machine availability, help you reduce machine downtime and increase your machine OEE performance. ...

What is manufacturing capacity analysis and how to perform it

A capacity analysis is an excellent solution for auditing a manufacturing plant and diagnosing the hidden capacity waiting to be unlocked. ...

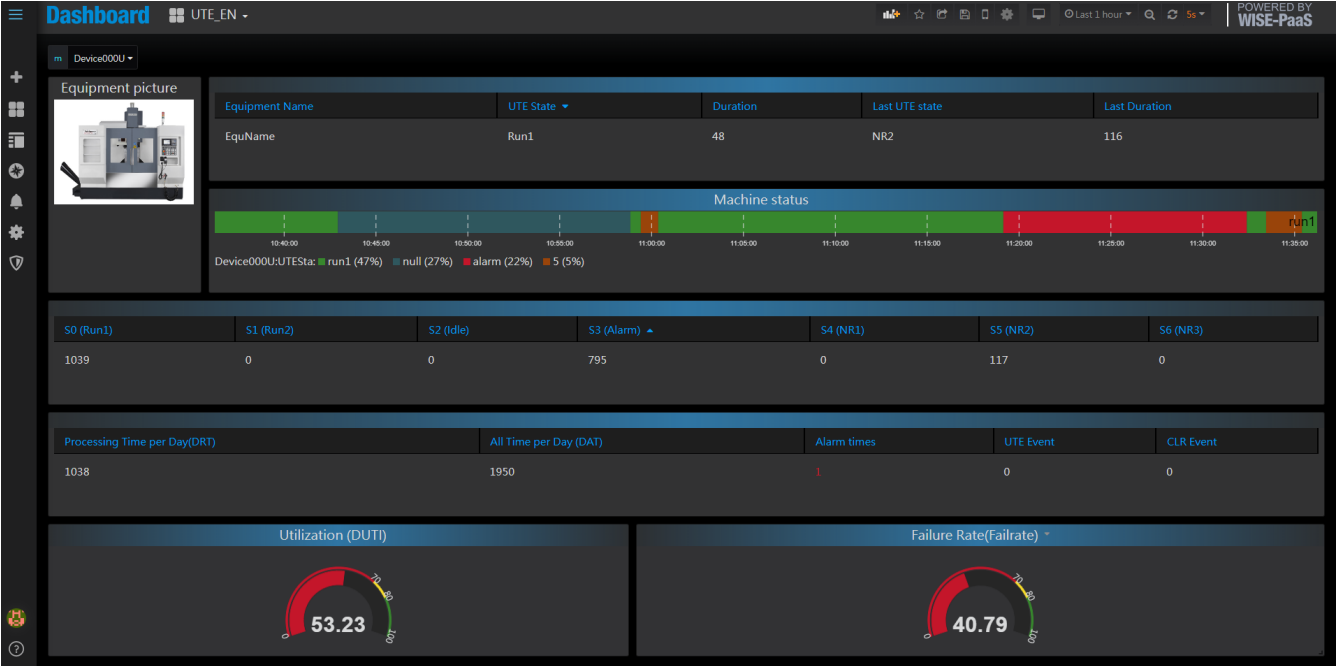

Machine Utilization: Track and Improve equipment performance

Harness the power of AIOT technology and platform, understanding your machine utilization level and Improve Performance of your whole plant. ...

Maximizing Production: Tips to increase Manufacturing Productivity

Knows the strategies that manufacturing businesses can use to uncover hidden capacity and increase productivity in your manufacturing factory ...

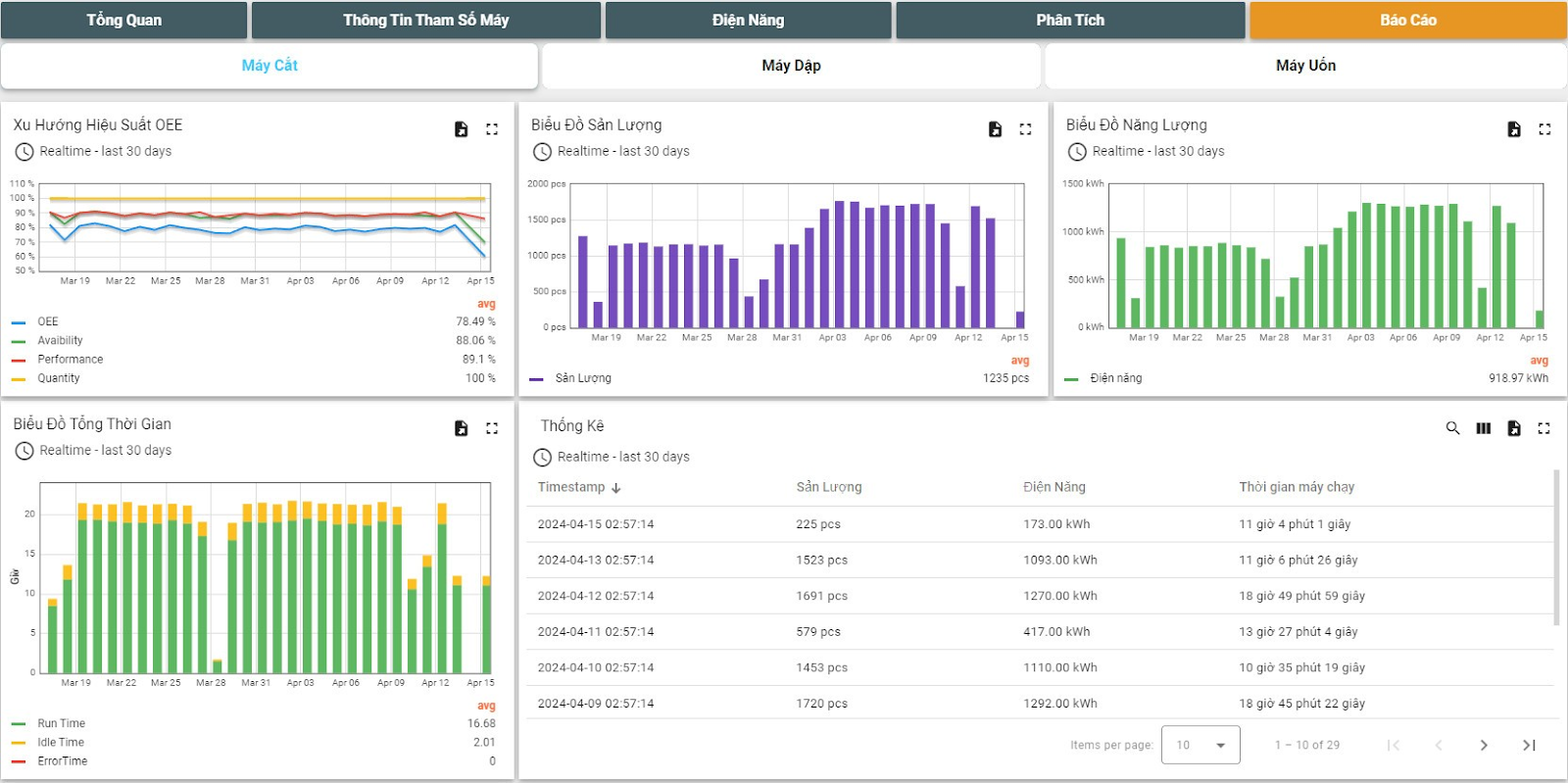

OEE – Overall Equipment Effectiveness: A comprehensive guide

With OEE, entrepreneur gain insight into optimal productivity challenges and how to improve your manufacturing operations. ...

Measuring and Optimizing Machine Productivity

Directly collecting data from equipment is the most effective approach to monitor and improve the machine productivity on the production line. ...

Machine condition monitoring: Improving machine health and OEE

Harness real-time conditions from their assets to monitor and optimize the maintenance and performance of their machines. ...

Oee software: How to track and improve productivity

In this data-driven world, OEE software solutions have emerged as one of the vital tools for factory optimization and continuous improvement ...

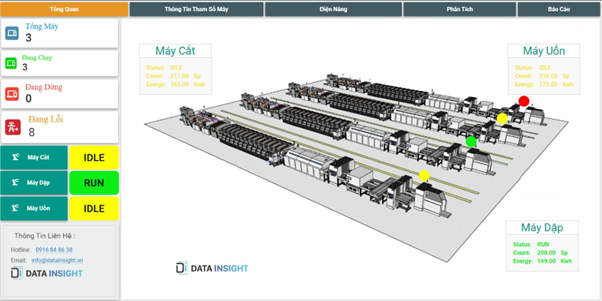

Visualizing Production Performance with OEE Dashboards

Collecting and analyzing OEE data to better understand how efficient their equipment usage is with an OEE dashboard. ...

HOW OEE SOFTWARE IMPROVES PRODUCTION EFFICIENCY

By factoring in variables, OEE software can determine how productive an operation truly is by measuring the effectiveness of the production equipment. ...

Improve efficiency in your plant with OEE calculations

Applying OEE calculations to identify causes of time or resource waste during production and improve efficiency in your plant. ...

OEE: YOUR BUSINESS NEW FINANCIAL KPI

OEE can turn into a leading indicator of what will happen and then use it to drive the overall financial performance of your enterprise. ...

7 STRATEGIES TO IMPROVE OEE

The 7 strategies to improve oee in manufacturing to better understand how to use your equipment and identify your major sources of waste. ...

Difference between OEE, OOE and TEEP

The main difference between OEE, OOE and TEEP is the time or Availability that is used in each calculation. ...

Di DATA INSIGHT TECHNOLOGY VIETNAM COMPANY LIMITED

- Tax ID: 0110062048

- Hanoi Office: 6 Kim Dong Street, Giap Bat Ward, Hoang Mai District, Hanoi City, Vietnam.

- HCM Office: 99 Cong Hoa Street, Ward 4, Tan Binh District, Ho Chi Minh City, Vietnam

Fanpage

© 2023 Data Insight. All rights reserved. Data Insight is a registered