Overall Equipment Effectiveness (OEE) is a methodology that has been around for many years. It is a straightforward system that measures a machine’s performance and productivity. By factoring in variables such as downtime associated with changeover, breaks, off-quality part fallout, and others, OEE software can determine how productive an operation truly is by measuring the effectiveness of the production equipment.

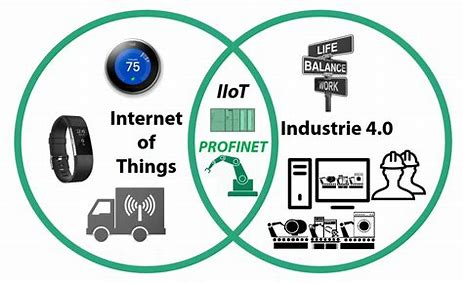

Today, OEE is being advanced using machine monitoring OEE software designed to take advantage of computing power to use OEE’s methodology to further understand and act upon variables that impact a company’s production efficiency. While OEE software in itself is not the end solution or goal, this proven methodology can be used in conjunction with cloud-based software such as an ERP system or with Industrial IoT platforms to enhance results that improve production efficiency and add to their bottom line.

Why Use OEE Software?

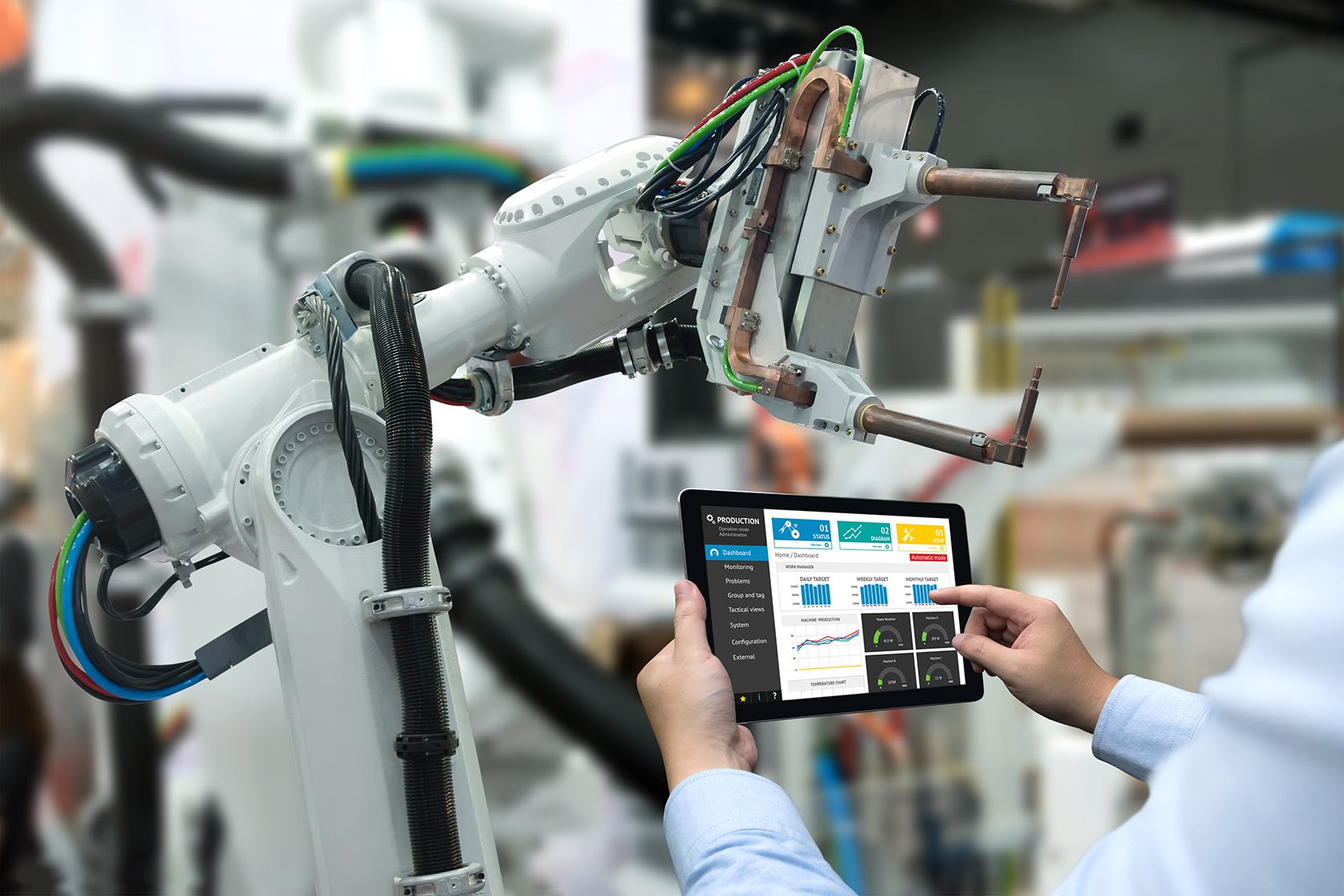

In the modern factory, complex production equipment is highly automated. And in addition to the actual production stations themselves, there may be support robotics, automated material handling, conveyance, and an abundance of other systems tied to production equipment. With those added mechanical, maintenance, and logistical pressures placed on operators and technicians to keep equipment running, the number of tasks and their complexity can be greatly increased.

OEE software uses that computing power to analyze these variables to develop an optimized response. The software can identify where effectiveness is faltering which allows managers to take steps to address issues. OEE software can also help determine whether the fall off is based on staffing, product complexity, equipment condition, or other variables.

This utilization of OEE software’s analytical capabilities is its key benefit. In complex manufacturing environments, operators, technicians, and managers are continuously acting upon these variables to improve production efficiency. But humans can make mistakes, risking lower production in the form of poor quality or added downtime.

One reason is that human based OEE calculation is manual and can be error prone. A second reason is that what may seem “intuitive” to human operators and managers, may at a deeper level be counterproductive instead. For example, the decision to increase speed of a specific piece of equipment may result in an increase in off-quality product. And while these are understood in general terms, the ability of OEE software to analyze a large block of data to a deeper degree will help arrive at an optimized speed that improves production efficiency while maintaining acceptable quality levels.

Likewise, OEE software can help balance effectiveness with production efficiency. One example is in the determination of staffing for a production line. While increasing the number of operators may make the equipment more effective, it may conversely make it less efficient with added labor creating costly idle time for staff. These examples show the strengths of being able to optimize OEE without sacrificing production efficiency, something not always obvious in manual OEE calculations.

OEE Software Applications

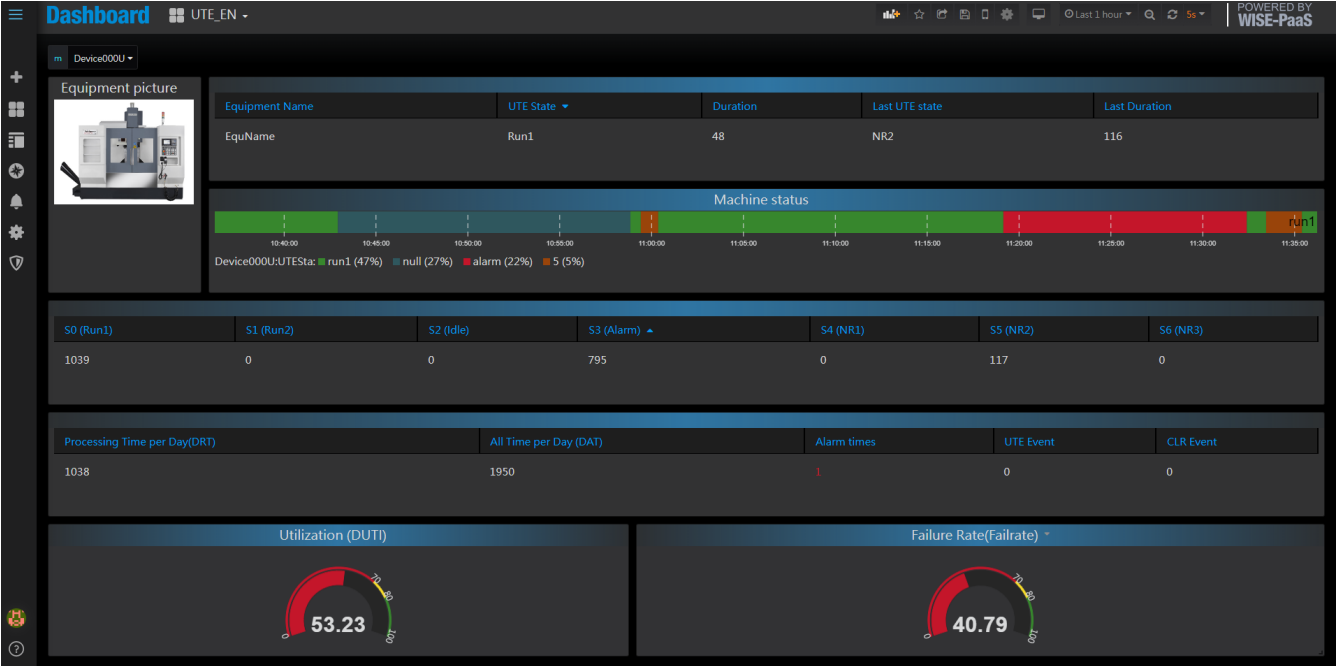

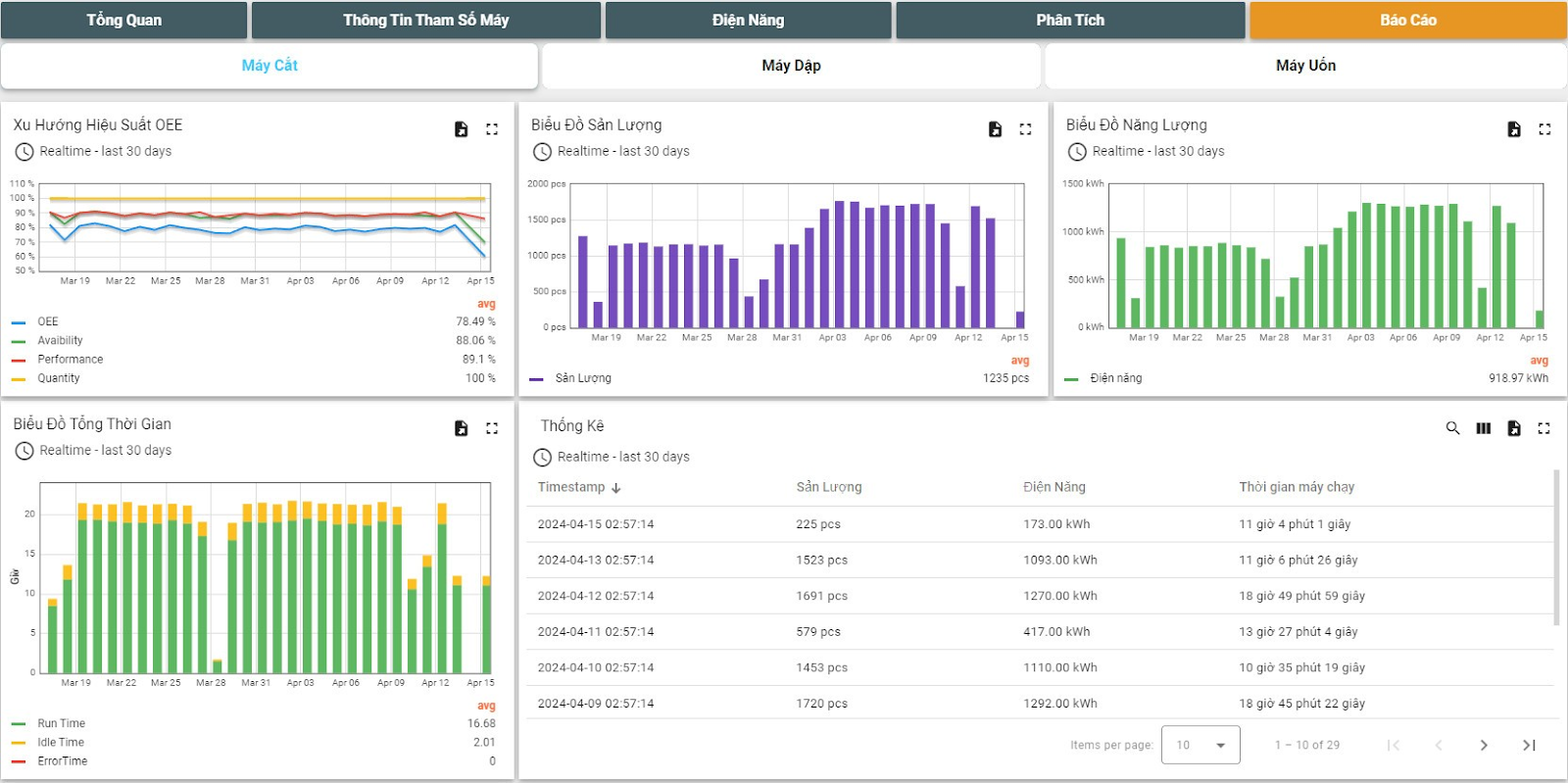

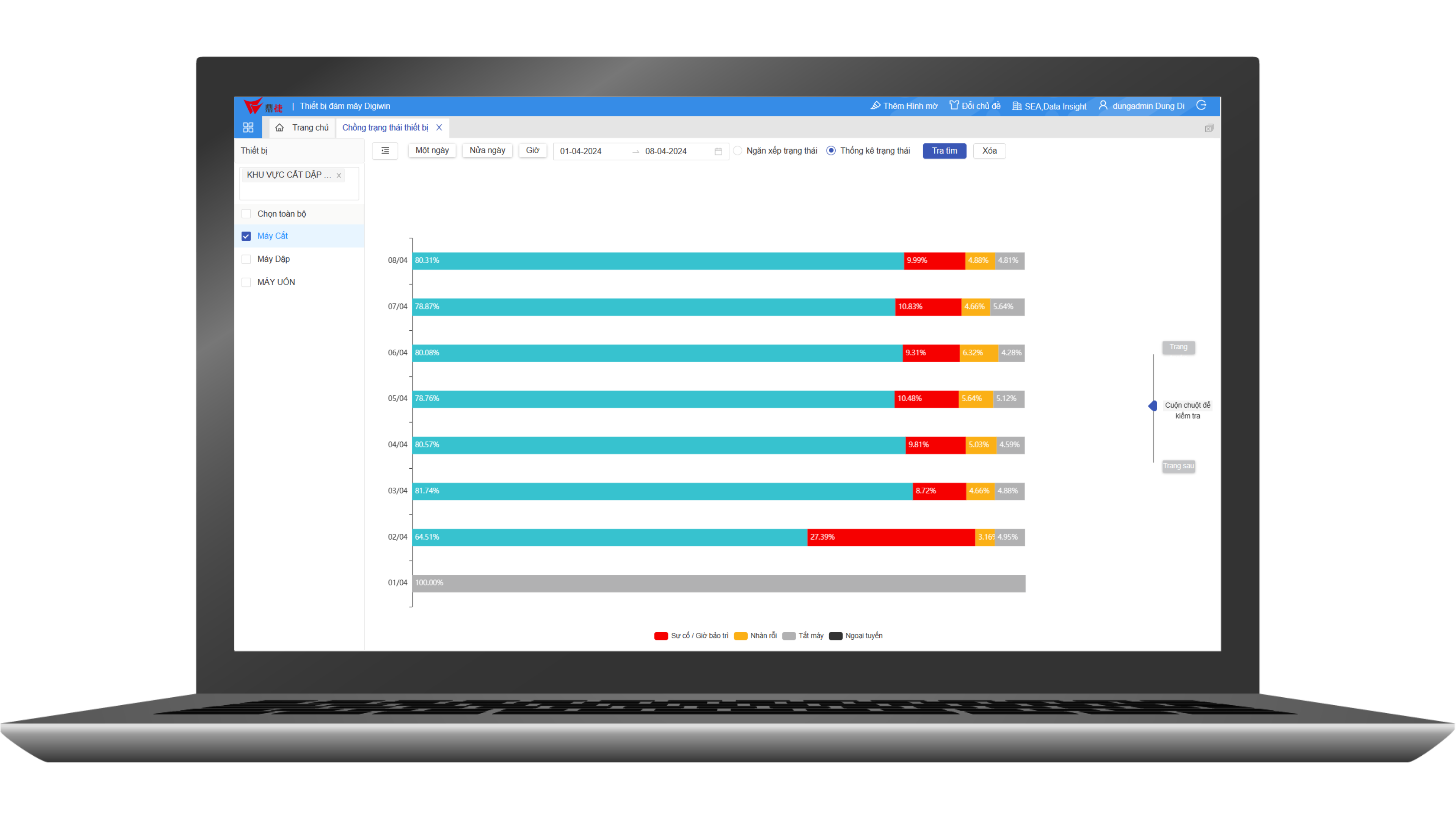

OEE is flexible in that it can be applied within a factory to measure equipment effectiveness in several ways. OEE software can be used to evaluate a specific piece of equipment to understand the variables impacting its performance. Mechanical, staffing, product mix, and other variables can be used with the OEE calculation at the single machine level to develop remedial action for improvement.

OEE software can also be used to evaluate the effectiveness of an entire production line which may include numerous sub-processing steps. Again, this level of complexity quickly reaches its limits with human calculation. And using software to analyze the data can help managers understand how and where to deploy resources for a specific production line or product line.

Finally, OEE software can be used at the factory level as a benchmark for understanding equipment effectiveness for the entire operation. Armed with a true representation of equipment effectiveness, managers can improve decision-making at a global level.

Each of these views offer flexibility to managers that would be difficult to maintain manually. By having different levels of analytical capability, process improvement and optimized SOPs can be developed to drive improvement through the operation to increase production efficiency.

OEE Software and the Connected Factory

When OEE software is utilized it can have a positive improvement to production efficiency. But where the software really begins to shine is when it is used in conjunction with the advanced sensors, real-time analytics and machine learning capabilities offered by Industrial IoT. It is estimated that when used within the context of a smart factory, OEE software can result in an overall improvement of OEE of as much as 21%.

Using OEE software in conjunction with an industrial IoT platform can improve factory OEE in several ways including:

- Using historical process and performance data to optimize schedules and maintenance activities.

- Tie into advanced warnings for factories using predictive maintenance.

- Establish deeper and more accurate process parameters for specific product runs.

- Identify areas where material and supply costs can be reduced based on accurate and historical analysis of actual volumes, allowing JIT production when applicable.

While these are but a few of the benefits available for utilizing OEE software, they highlight the fact that it can be used as part of an overall manufacturing analytics ecosystem. In conjunction with other software such as those for scheduling and forecasting, ERP or MRP and others, these area specific platforms benefit significantly from the increase of data and data accuracy from sensors and edge devices in place with IIoT.

All stand alone software platforms rely on data input, and human data gathering can be error prone and time-inhibited. But by using these systems in conjunction with IIoT, the data and analytics of the IIoT platform can drive larger volumes of accurate and deep data, collected in real time, to the area specific platforms, enhancing their effectiveness.

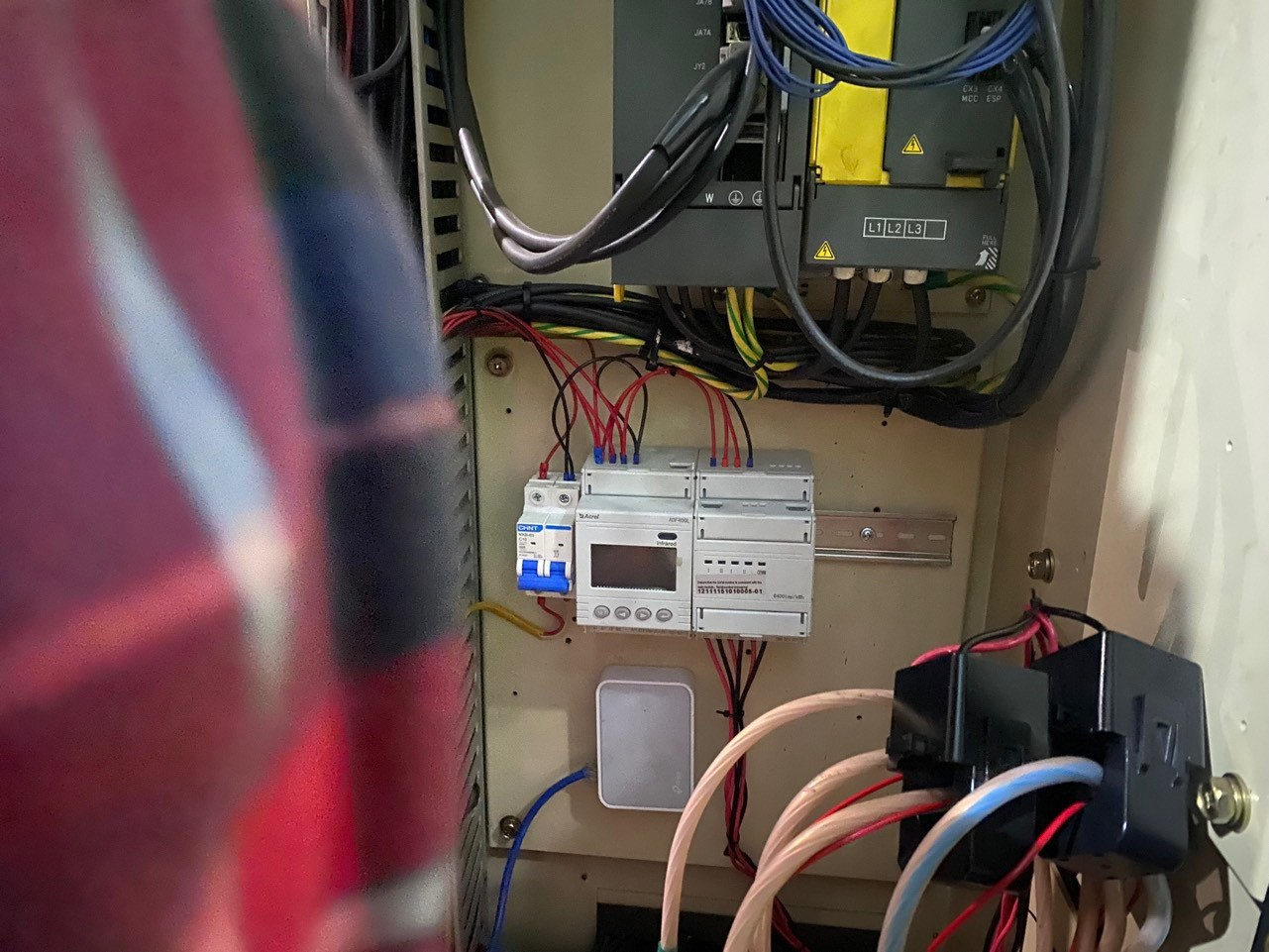

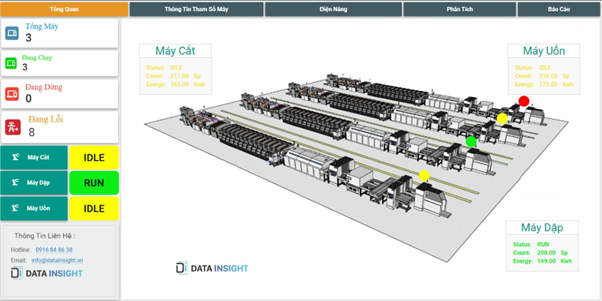

Utilizing OEE software in conjunction with IIoT has other benefits as well. For one, these systems are capable of providing visualization of the shop floor across a range of functional areas that can feed directly into ERP, scheduling or OEE software. This places the benefits and functionality derived from those systems into the hands of operators, technicians, mechanics and decision-makers in real time.

Secondly, as data is un-siloed and standardized across the connected equipment, the data flowing into software such as OEE is consistent and recognizable to all functional areas. This creates the elusive “single version of the truth” so that the experience is global and optimized across the entire enterprise.

Using OEE Software to Improve Production Efficiency

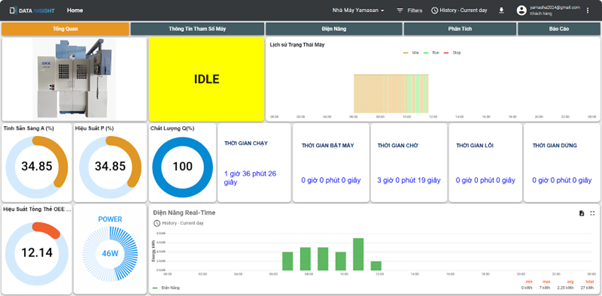

OEE software uses accurate data, strong analytics, and faster calculation of basic machine data to determine the effectiveness of equipment. By replacing manual calculations with software-based calculations, it can be effectively used for a single piece of equipment as well as broadly at the factory level to assess a factory’s true OEE. And this experience is vastly improved when that data is captured in real-time from IIoT connected equipment at rates and volumes not possible with human intervention.

By using this data, operators, technicians and managers can spend more time developing improved processes that adhere to an optimized OEE and spend less time guessing. The impact on production efficiency will grow as OEE improves. And when combined with IIoT as well, those improvements in production efficiency can also encompass better labor and shift scheduling, improved decision-making, and better quality.

If you’re interested in how Data Insight provide you our OEE software, improve efficiency of your plant and drive profit for your business, don’t hesitate to schedule a demo with our team.

Contact us now at!

DATA INSIGHT TECHNOLOGY VIETNAM COMPANY LIMITED

- Hotline: 0916.848.638

- Hanoi office: Số 6 Kim Đồng, phường Giáp Bát, Quận Hoàng Mai, Thành phố Hà Nội, Việt Nam

- HCM City office: 99 đường Cộng Hòa, Phường 4, Tân Bình, Thành phố Hồ Chí Minh, Việt Nam